Key License Terms:

Issued: 27 July 2004

Valid: 1 October 2028

Area: 3.3 km2

The Tardan exploration and mining license area is 3.3 km2 (and is contained entirely within the Greater Tardan license area) in the Republic of Tyva, located approximately 78 km from the regional capital Kyzyl.

It is accessed by a 70 km paved road from Kyzyl, with the final 18 km via a graded road.

The Tardan property is 100% owned by Auriant Mining.

The Tardan deposit itself is a block bounded by tectonic fractures which are part of the Baisyutskiy shear fracture. The total area of the block is approximately 4.0 km2 and is underlaid by volcanic and carbonate sediments of the Tumattayginskaya and Vadibalinskaya formations with intrusions of the Tannuolskiy complex.

The most common rock type is marblized limestone of the Cambrian Vadibalinskaya formation. Aproximately 20-25% of the Tardan deposit area is underlaid by granitoids of the Cambrian Tannuolskiy complex of which diorites are the most common.

The major structural elements of the deposit are faults on the contacts of granites (diorites) with the host and carbonate rocks.

The main tectonic features can be are grouped into three main systems:

-

Northeast striking Changysskiy and East faults

-

Northwest striking faults with a gentle dip to the southwest

-

Northwest striking faults

The relatively simple structure of the deposit is influenced by the Changyssky fault zone of a northeastern direction (40-50°). This fault zone defines the setting of the Tardansky graben, which results in a pronounced asymmetry in the structural plan of the Tardan deposit ore field.

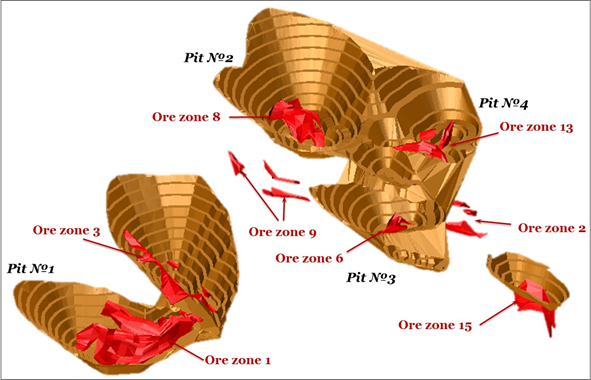

The Tardansky graben is located in the central part of the deposit, and extends diagonally from ore zone 1 to the northeastern part of the license area and further to the northeast to the Barsuchy prospect. The width of the graben varies from 590 m in the vicinity of ore zone 1 to 460 m in the northeastern part. On the northwest the graben is bounded by the Changyssky fault, in the southeast - by the Vostochny fault. The Tardansky graben includes ore zones 1, 3, 6, 7, 8, 13, and these are the main minable gold reserves of the Tardan deposit.

The tectonic faults of the Tardan ore field are represented by thrusts and shifts. According to the geological structure, the structural features and mineral composition of the ore field correspond to gold skarn type deposits.

Previous exploration work in the ore field identified 14 ore zones containing 41 ore bodies. Another two ore zones, 6a and 15, were explored in 2013. The ore zones bring together a group of ore bodies, placed in a single metasomatic-hydrothermal field and tectonic structure, with common strike and dipping, and separated from each other by large blocks of unaltered rocks.

Virtually almost all of the ore zones are located in contact limestones of Vadibalinskaya formations and diorite sills of the Tannuolsky complex.

The width of the various ore zones, which include several individual ore bodies, varies from a few metres to 30 -50 m, with strike lengths of hundreds of metres.

The ore bodies are linearly elongated bodies of hydrothermally altered sulphide skarns with complex inner morphology. The length of the ore bodies is between 20 and 150 m, with the width between 1 and 13 m.

| Classification | Tonnage | g/t | 000 oz | kg |

| TAILINGS | ||||

| Heap leach tailings | 2,108,950 | 0,97 | 66 | 2,047 |

Mining

All ore extraction at the Tardan deposit is done via open pit mining. In 2013 there were 4 open pits in operation where gold bearing ore was mined. The ore bodies are relatively deep averaging about 150 m in depth, requiring a lot of stripping of overburden, leading to a stripping ratio of 7.2 m3/t. Ore and waste is primarily mined using explosives and then trucked although, depending on the rock type, some minimal mining is done with bulldozers without needing to be blasted first. Once the ore is loose, it is then scooped up with large excavators and transported to the heap leaching site 2.8 km away using large dump trucks. Waste material from stripping operations is piled near the open pits with bulldozers. Mining is a non-stop operation, using two 11 hour shifts per day.

In 2013 mining operations mostly focused on Pits Nos.1,2,3,4 with 269,300 tonnes of ore mined, which required almost 2 million m3 of stripping (partly reflecting limited stripping and mining activities in 2012). This ore, averaging 1 - 1.5 g/t is then mixed with higher grade gravitational tailings of 3 - 4 g/t stockpiled from previous gravitational processing of ore.

Ore processing

At Tardan there are two plants for processing ore and extracting gold.

Gravitational Plant

The gravitational plant was commissioned in April 2007 and was designed to process high grade ore and involves the mechanical extraction of gold from the ore. The ore is initially crushed and then milled to 74 microns and then passed through a magnetic separator which separates ore containing iron, thereby increasing the concentration of gold. The ore is then fed into a Knelson centrifugal separator that further concentrates the gold. Following this separation the solution containing the gold is passed over vibrating gravity tables that collect the gold particles. These particles are then smelted on site into dorè bars.

The gravitational plant was temporarily closed in 2012 when the heap leach operation and plant was commissioned.The plant was re-opened in 2014. Over the five year period of its operation the gravitational plant produced 780 kg of gold.

Overview of Heap Leaching the Tardan mine

Heap Leaching

Heap leaching is a relatively simple and cheap method of producing gold from suitable ore. The mined ore is crushed to 10 mm or less, mixed with stockpiled gravitational tailings in a ratio of 60:40 ore to tailings. Following this the mixture is then coated (agglomerated) with cement, turning the crushed material into a granular form which ensures that fine particles of ore do not clog the irrigation systems and that the heap does not collapse.

Following cement agglomeration, the ore is transported via a conveyor to a radial stacker which stacks the ore on to the heap leach pad, up to a height of 7 m. The heap leach pad is a specially prepared area, with a gentle slope, that is covered by a thick non-permeable layer of polymer film that ensures no solution passes into the soil.

The heap is then irrigated with pipes and sprinklers that contain a weak sodium cyanide solution. This solution percolates through the ore in a 120 day cycle and dissolves gold into solution. The solution drains away at the bottom of the heap and is then piped to the heap leaching plant where gold is extracted from the solution using activated carbon in large sorbtion columns. The solution, which now does not contain gold, is then recycled back to the heaps.

From the sorbtion columns gold is then desorbed from the activated carbon using a hot caustic solution, and then goes through an electrolysis operation where gold is deposited on cathodes, which are then smelted into dorè bars containing not less than 70% gold (along with copper, iron and silver). The gold dorè is then shipped to specialized precious metals refineries in Russia where it is smelted into pure gold.

Seasonality

Given the climatic conditions, gold production is seasonal. This is primarily due to the need to use cement agglomeration of the crushed ore prior to stacking. As the cement uses water, in very cold weather even warmed water freezes meaning that agglomeration cannot take place, and hence no stacking occurs, however irrigation of the heaps continues throughout the winter as the cyanide solution can be warmed. As no fresh ore is stacked, gold production drops significantly during the December - May period.